Temperature directly controls the solubility of cannabinoids, so it’s essential to be able to control the temperature in the system.Ĭlosed-loop extraction systems also prevent the solvent from being evaporated into the atmosphere and allow the solvent to be used many times without needing to be recharged. In addition to controlling temperature, closed-loop extraction systems are excellent at regulating temperature. High pressure allows for maximum extraction of cannabinoids. EfficiencyĪnother closed-loop extraction benefit includes a higher-pressure capacity than open-loop extraction equipment. In fact, in our several thousand installations, we have never had a client have a safety issue or accident with Precision equipment. A contained system makes the risk of hazard almost non-existent. In closed-loop extraction systems, there are no opportunities for leaks if the equipment is maintained and operated at the appropriate standards. Hydrocarbon solvents are flammable, pressurized gases. Cannabis industry professionals regard closed-loop extraction as the safest way to extract cannabinoids. One key closed-loop extraction benefit is safety.

The key closed-loop extraction benefits include safety, efficiency, cost-effectiveness, and higher quality products. In that case, more plant matter could be extracted in a smaller extractor. As the density of the plant material column can be increased as well, the production per extraction is increased as well. This larger solvent tank allows much faster extraction speeds as well as being able to hold all the required solvent that allows much greater control over the contact time, contact temperature, contact pressure, and polarity of the solvent as it passes through the plant material. The system is not only safer, but faster because its tanks hold all the solvent and a complete extraction could be performed in a single pass. When the plant matter is filtered away and the solvent is recovered for reuse using a passive process in a closed system, the process is completed. In this new solvation extraction process whereby the plant material is saturated with an adequate volume of a chosen solvent until all the target chemical compounds are dissolved at which time they are carried away from the plant matter using a specific flat micron size filter. Upon completion of the run, extract removal is made simple by adding a removable bottom to the collection base.As a truly closed system, all extraction and solvent recovery processes are operated within the confines of the coded and rated tanks and lines. An inline ball valve is used to allow the solvent to be suspended in the material column, as well as closing the collection base off during recovery. Professional: This model features upgrades to help produce extract easier. This model has minimal features to keep cost low while providing the necessary equipment to get the job done. Comes with a welded bottom base and stainless reclaim container. Once collected, the solvent in this passive unit is distilled and recovered using temperature manipulation, leaving oils in the collection base.Įxplorer: Our standard, most economical setup, perfect for the entry level extractor on a budget. Solvent washes through the material column and collects oils as it passes over the material, and the oil-bearing solvent is collected in the collection base. The top-fill closed loop extractor is the safest way to do hydrocarbon extraction. Being a small version of our standard top fill closed loop extractor, this is also great for beginners and has all the same bells and whistles as our larger options.

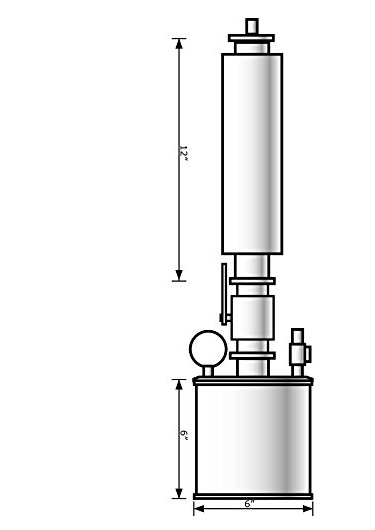

It is an excellent option for small personal runs or test runs and is the perfect size for a table top.

This is the Best Value Vacs MINI Extraction System. Check with your local fire marshal for guidance when operating indoors Closed Loop Reclamation Extraction System (Comes with 1 yr. Use only in extremely well-ventilated areas. DISCLAIMER: This unit is intended for LEGAL purposes only, to be used in accordance with local laws and ordinances.

0 kommentar(er)

0 kommentar(er)